Series 350-T

Product Highlights

Modern glazing from Fleetwood coupled with increasingly efficient insulation techniques allows a minimalist design with huge glass that does not compromise energy consumption.

Thermal Break Technology:

Fleetwood products with a “T” in the series number are manufactured with thermally broken aluminum for condensation control and energy efficiency. For over 30 years, Fleetwood has designed products around this now sweeping practice and does so with extensive testing and engineering so the product maintains the look for the ultimate minimalist.

Security Benefits:

Fleetwood endeavors to make products better instead of cheaper, resulting in specialty products that other manufacturers should not attempt. High-security laminated glass (like your car windshield) coupled with robust Fleetwood framing can withstand severe impact.

Noise Control:

Fleetwood chooses to offer a wide range of options instead of limiting features to increase profit and simplify production. Sound dampening upgrades to glass and products are available without affecting the budget or design.

Fleetwood’s design focus is the opposite of mass production. A prime example is the sharp edges and crisp lines created by a balance of hand tooling, automation and dedicated machining.

Heavy Walls:

It does not take a professional to realize the hidden engineering in each Fleetwood system. The aluminum wall thickness greatly exceeds most, if not all other windows. Any user will immediately experience its sturdiness and palpable luxury when they operate the window.

Steel Window Look:

Steel Window Look: The Series 350-T is offered with a simulated divided lite which resembles a classic steel window beveled design. This allows the “Steel Look” without the inherent complications and limitations of steel products.

Custom Configurations:

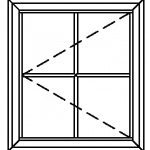

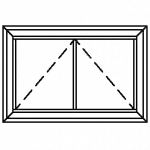

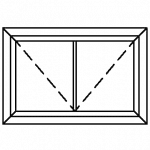

One of the features of the Series 350-T is its flexibility. We can create a window wall that contains several different window types (e.g. fixed, casement and awning) with seamless transitions and slender lines.

Aluminum is thermally stable in that it does not swell or shrink when the temperature or humidity levels change. Very little energy is lost through the frame material but in the case of wood and vinyl, energy is lost through the frame and vent seams after years of expansion and contraction.

Welded Corners:

The frame and vent corners are hydraulically joined together with a robust corner key. They are then spot welding to make them even stronger, making it possible to have a casement vent up to 3’ x 8’, which rivals the size of a typical door.

Leak Prevention:

To assist builders with a waterproof installation we offer an integral nail-on fin as part of the frame. Other window manufacturers attach a separate add-on fin. This short cut can cause water leak issues years down the road.

Low Maintenance:

While every lifestyle product requires upkeep, Fleetwood products are resilient in even the extreme environments and come with a Lifetime Warranty.

The Series 350-T comes standard with multiple contemporary hardware choices for the ultimate minimalist. All hardware is designed for longevity in even the harshest environments.

Full Length Latching:

The standard latch is our multi-point lever. When this latch is engaged, the window is cinched into a closer union with the main frame, giving you the most secure latching device on the market.

Thick Walled Screen Frame:

The Series 350-T screen is constructed of heavy gauge extruded aluminum and is attached to the main frame with sleek, stainless steel clips (ASC). Screens from Fleetwood will not compromise the design integrity.

Product FEATURES

1″ Insulated Glass with Dark Bronze Spacer

6063 T-6 Extruded Aluminum

Poured & De-bridged Thermal Barrier

Strut Thermal Barrier (Interlockers & Perimeter Frame)

2-1/4″ Deep Nail-on Frame

Stainless Steel Assembly Screws

Welded Corners & Bolster Key

1/2″ Height Aluminum Sill Pan

Brushed Nickel Roto Gear Hardware & Folding Handle (Casement & Awning)

Steel Single-Arm / Gear

Stainless Steel Concealed Hinges (Awning & Hopper)

4-Bar Hinges & Ring Cam Handle (Hopper)

Stainless Steel Butt Hinges (Casement)

Equal Sized Glass

Exterior Snap-in Glazing (Square Profile Stop)

Extruded Screen Frame with UltraVue Mesh (Phifer.com)

Finish:

-

- Kynar 70% Paint (50% for dark colors, ex. Black)

- Class 1 Custom Anodize (Light Bronze & Medium Bronze)

Glazing: 1/4″, 9/16″, 1-1/4″ & 1-1/2″

2-1/4″ Deep Equal Leg (Block) Frame

2-1/4″ Deep Unequal Leg (Block) Frame

Unequal Size Glass (TDL Alignment)

Steel Look SDLTruth Stainless Steel Arm / Gear (For Roto Gear Hardware) (Casement & Awning)

Knob Handle (For Roto Gear Hardware) (Casement & Awning)

4-Bar Hinges & Cam Handle (Casement & Awning)

Cam Handle or Spring Latch (Hopper)

Black Painted Hardware Finish

“STEEL LOOK” simulated divided lites

Fleetwood has introduced a variety of new “Steel Look” SDL options for the minimalist designer wanting to match the classic look of steel, but also wanting to avoid the cost and complications of steel manufacturing.

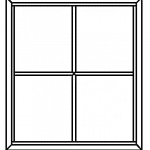

Fixed

Casement

Awning

Hopper

Technical Resources

- 350-T-01__Casement (PDF) (DWG)

- 350-T-02__Awning (PDF) (DWG)

- 350-T-03__Hopper (PDF) (DWG)

- 350-T-04__Fixed_Special_Geometry (PDF) (DWG)

- 350-T-05__Steel_Look (PDF) (DWG)

- 350-T-06__Fixed_Inside_Glazed (PDF) (DWG)

- 350-T-07__Hinge_Screen_Casement (PDF) (DWG)

- 350-T-08__Hinge_Screen_Awning (PDF) (DWG)

- Anchor Location Worksheet (PDF)

- A Awning with 4 Bar Hinges and Cam Handles

- A Awning with 4 Bar Hinges and Roto Operator

- AA Awning with 4 Bar Hinges and Roto Operator

- A/O Awning with 4 Bar Hinges and Roto Operator

- C Casement with 4 Bar Hinges and Cam Handle

- C Casement with Butt Hinges, Roto Operator, and Multi-Point Lock

- CC Casement with 4 Bar Hinges and Cam Handles

- CO Casement with 4 Bar Hinges and Cam Handle

- H Hopper with 4 Bar Hinges and Spring Latch

- HH Hopper with 4 Bar Hinges and Spring Latches

- General Installation Instructions (see Windows)

- Series 350-T Installation Instructions

- Series 350-T Typical Wall Conditions

- Series 350-T & 450-T Limit Device Installation Instructions

- Series 350-T WOCD Installation Instructions

- Screen Clip Installation Instructions

- FL14904.8 R8 Non-Impact Casement

- FL14904.9 R8 Non-HVHZ Casement

- FL14904.10 R8 HVHZ Casement

- FL14904.14 R8 Non-HVHZ Casement Wet

- FL14904.15 R8 HVHZ Casement Wet

- FL14907.5 R10 Non-Impact Awning

- FL14907.6 R10 Non-HVHZ Awning

- FL14907.7 R10 HVHZ Awning

FL#14904 (Casement/Inserts)

FL#14907 (Awning/Inserts)

/NFRC_std_glass.jpg)

/NFRC_std_glass2.jpg)

II. Additional Glass Testing:

NFRC Series 350-T Casement (PDF)

NFRC Series 350-T Casement NonTB (PDF)

NFRC Series 350-T Awning (PDF)

NFRC Series 350-T Awning NonTB (PDF)

NFRC Series 350-T Hopper (PDF)

NFRC Series 350-T Hopper NonTB (PDF)

NFRC Series 350-T Fixed (PDF)

NFRC Series 350-T Fixed NonTB (PDF)

Simulated Performance Alternative Reports are available upon request.

Spacers

- A1 = Aluminum Spacer

- SS-D = Stainless Steel Spacer

- A2/TS-D = Warm Edge Spacers

- ZF = Super Spacer

Linked reports reflect current testing to NFRC standards. If you have a suggestion for testing an additional type of glass, please email your suggestion to sales@fleetwoodusa.com.

All testing was performed in a laboratory environment to determine results. These reports are provided to allow Engineers, Architects, and Design professionals reasonable expectations of products and may not illustrate every option, condition, or configuration available. These are for illustration and comparative analysis only.

*Reports exceeding 4 years may not have current 3rd party certification, and will not be labeled.

Current Test Reports:

041714+AAMA_1886+Impact+350-T_Awning_65x42_01991059: (PDF)

041714+AAMA_CSA-SI+Non-Impact+350-T_Awning_65x42_01991058: (PDF)

041714+HVHZ_TAS+Impact+3800-T_350-T_X_65x42_01991030:(PDF)

062514+Comp_Analysis_350-T-3800_Non-Impact_Glazing: (PDF)

092313+HVHZ_TAS+3800-T_350-T_X_O_01990816: (PDF)

092713+AAMA_1886+Impact+350-T_Awning_OAO_42x180_01991061: (PDF)

092713+AAMA_1886+Impact+350-T_Casement_42x72_01991057: (PDF)

100313+AAMA_CSA-SI_3800-T_350-T_X_O_01990817: (PDF)

100513+AAMA_CSA-S1+Non-Impact+350-T_Awning_OAO_42x180_01991060: (PDF)

100513+AAMA_CSA-S1+Non-Impact+350-T_Csmnt_42x72_01991056: (PDF)

102215+AAMA_CSA-S1+Non-Impact+350-T_Fixed_PG35_48x120_T15-083: (PDF)

102215+AAMA_CSA-S1+Non-Impact+350-T_Fixed_PG50_48x120_T15-082: (PDF)

102821+86-96+Impact+3800-T_350-T_Csmnt_01993390: (PDF)

102821+AAMA_CSA-SI+Impact+3800-T_350-T_Csmnt_01993389: (PDF)

102821+TAS+Impact+ 3800-T_350-T_Csmnt_01993391: (PDF)

110215+AAMA_CSA-S1+Non-Impact+350-T_Fixed_Mulled_PG35_181x96_T15-085: (PDF)

111915+AAMA_CSA-S1+Non-Impact+350-T_Fixed_OO_PG40_108x72_T15-084: (PDF)

111915+AAMA_CSA-S1+Non-Impact+350-T_Fixed_Stacked_Mulled_PG35_120x96_T15-086: (PDF)

Archived Test Reports:

030298+AAMA+Non-Impact+350-T_Fixed_72x72_A98F-016: (PDF)

040698+AAMA+Non-Impact+350-T_Csmnt_24x48_A98C-047: (PDF)

041714+1886-96+Impact+3800-T_350-T_DP65_X_65x42_01991029: (PDF)

041714+AAMA_CSA-SI+Non-Impact_3800-T_350-T_DP65_X_65x42_01991028: (PDF)

042997+AAMA+Non-Impact+350-T+Awning_48x34_A97P-068: (PDF)

042997+AAMA+Non-Impact+350-T_Csmnt_72x50_A97C-067: (PDF)

060398+AAMA+Non-Impact+350-T_Hopper_Awning_Fixed_62x134_A98P-064: (PDF)

082300+AAMA+Non-Impact+350-T_Csmnt_72x72_A00C-077: (PDF)

092313+1886-96+Impact+3800-T_350-T_X_O_01990818: (PDF)

100313+AAMA_CSA-SI+Non-Impact+3800-T_350-T_DP65_X_42x84_01990815: (PDF)

101697+AAMA+Non-Impact+350-T_Fixed_72x72_Annealed_A97F-148-A: (PDF)

101697+AAMA+Non-Impact+350-T_Fixed_72x72_Tempered_A97F-148: (PDF)

111202+AAMA+Non-Impact+350-T_Fixed_72x72_Inside-Glazed_A02F-203: (PDF)

111202+AAMA+Non-Impact+350-T_Fixed_72x72_Outside-Glazed_A02F-204: (PDF)

122001+Dade+Impact+350-T_Awning_72x36_03-31366.03: (PDF)

122701+Dade+Impact+350-T_Fixed_84x72_03-31366.02: (PDF)